Xopax machines are now CE compliant! Our European friends will be happy to know that we have now passed all requirements in order to be fully CE compliant. We can now affix this little logo to our product and distribute to any country within the European Union. The process was a little daunting at first but once we did our research and read the requirements it wasn't too tough. We know that we build a quality machine that is not only durable but also safe. Every precaution to protect the end user has been made but we were still a little nervous about the whole "testing" concept. Maybe it is left over paranoia from school days? Well, turns out there was nothing to worry about. We had zero problems to deal with! So, cue the music and toss your hats, it is time to celebrate the Xopax graduation!

1 Comment

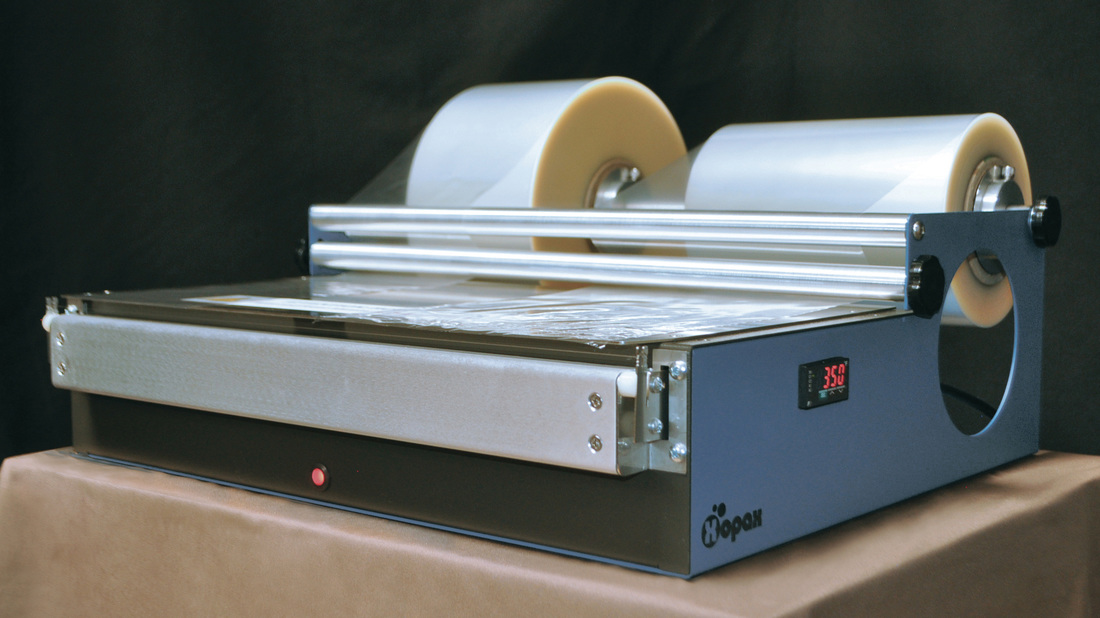

I got into the CD duplication business in 1998 because it seemed like something fun. It started as a hobby and a way to convert my DAT tapes to a media that I could listen to in my car. Before I knew it we were fully occupied with everything from duplicating CDs and DVDs to printing and then wrapping. As a small time operator without the budget for wrapping machines that cost upwards of $50,000.00, we like many others, looked for a solution that was less expensive and easier to maintain. Understanding that manual labor would be involved in order to bring the price point down on the machinery we began our journey.

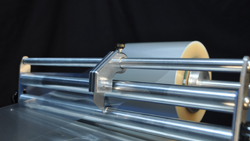

At the time our options were a variety of shrink wrap machines and a couple of choices for manual over wrapping. The over wrapping machines were pretty clumsy, unreliable and the consumables were expensive. So we picked shrink wrapping as our solution. Spent over $3,000.00 for a semi-auto unit and have honestly never liked the machine. We still use it for certain ultra thin projects like eco sleeves but there have been more curse words uttered at this particular piece of gear than anything else we have ever owned. In addition to our own distaste for this method our customers also didn't like it. Most of them wanted the more professional looking folded corner of an over wrap method. So we moved on to over wrapping. After sorting through the existing products out there that met this criteria of low price, low cost consumables and somewhat efficient use we developed our own product. We have been manufacturing Xopax machines now for over two years and couldn't be happier. The product has been incredibly reliable and we use it daily in our CD and DVD duplication business. Not only are our duplication customers happy with their retail ready disc packages but we've sold hundreds of these to companies all over the world to wrap not only CD and DVD products but a myriad of other products as well. We also built a tear strip option which made our customers even happier. It's somewhat ironic to me that one of the most difficult segments of our optical disc production facility isn't the technical aspects of making quality discs but the plastic wrap that we finish it with. We work hard to make it look perfect and then they pull the tear strip, peel away the plastic film and... throw it away! Here are some YouTube links that relate to this topic: CD Jewel Box Overwrapper CD Slimline Jewel Box Wrapping Machine Tear Strip Accessory  Yes, we have a new accessory that embeds tear tape which then easily opens the package. You know how hard it is sometimes to get your finger nail into one of these wrapped corners or find something sharp to get the box open. Right? I'm always silently grateful whenever a box I'm trying to open has one of those handy little pull tabs. This is one of those little things that separate Xopax from the rest of the field. Besides being a superior machine in all aspects we now have the ability to make life easier for end users to open their product. If you are trying to bring the best possible product to market then this is icing on the cake. Hats off to Wil Palmer for designing this for us, he did a great job. It is extremely easy to use and does not interfere with the normal wrapping process. The tear strip is bonded to the film as it passes through the rollers so the person operating the machine never has to think about it. When the wrap is finished there is a short end that is easy to see and use I know the first question is always how much does this add to the cost of wrapping? Well for starters, this new accessory ships with one roll of clear tear tape, so you're good to go for a lot of wraps. So, for example, the cost of this material for a standard CD Jewel box is about one third of a penny! There is a whopping 30,000 feet of tape on each roll so you will only need to purchase one of these for every 6 rolls of wrapping film. We hope this will help fill a need and also separate our product from the rest of the field. Check out this video for a better understanding of how it works. Requires Accessory Bar Let's say you have different box sizes for your products and you want them all over wrapped with clear poly film with neatly folded corners and you only have one machine in your budget. Sounds tought but it's really not. There are three basic ways to accomplish this with the Xopax wrapping machine.

Do you have multiple box sizes and don't want to buy film for each size?

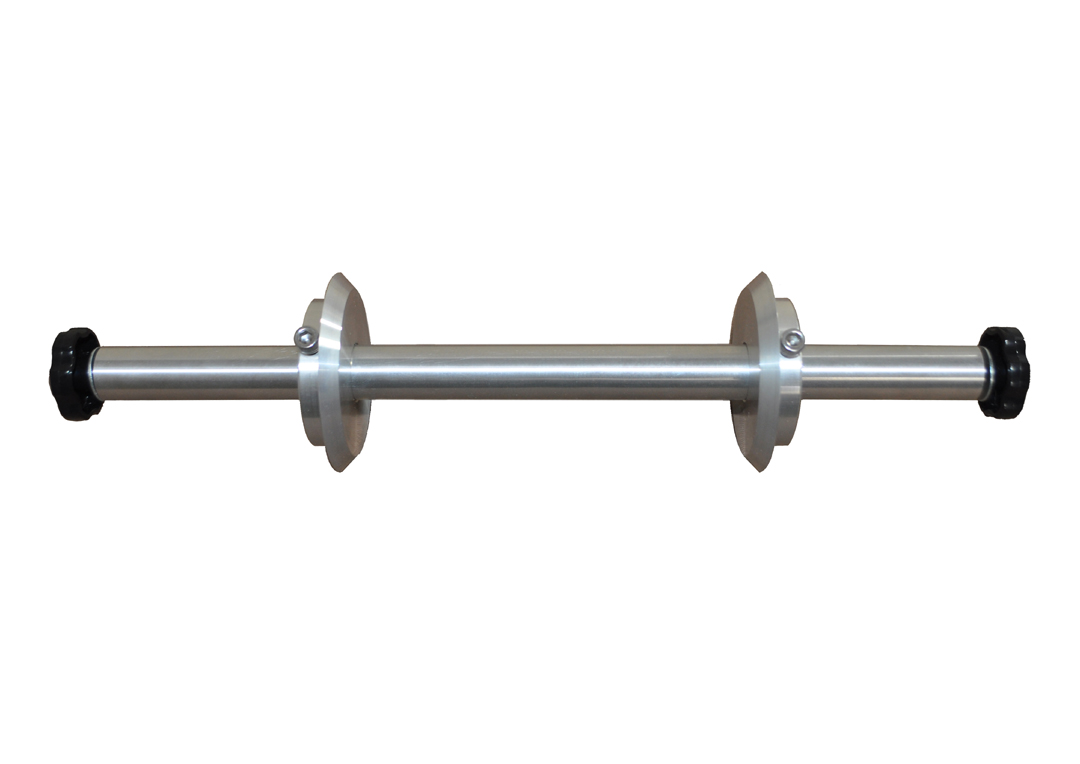

Well, sit back and relax because your troubles are over. Introducing the all new Cutter Assembly from Xopax. Made of solid aluminum and designed to use easy to find razor blades make this a "must have" for anyone who has multiple size boxes and needs to change from one size to another quickly. While engineering this tool we knew that safety was a huge concern. Please note the blade is pointed away from the operator and that changing its position is easily done with the thumb screw located at the top of the tool. When not in use the assembly can be easily store at one end of the utility bar with the blade pointed in a safe direction. Want to see it in action? Check out this video. When purchasing this accessory please note that the Accessory Bar is required. There is of course no solid answer for this. We routinely tell people to give themselves at least 100 wraps before they start to get the "hang" of it. We base this on actual experience in teaching people in our own production house where we produce CD and DVD packages. Depending on the individuals abilities we see varying degrees of initial success. I like to equate it to learning a musical instrument which in my case is a guitar. When I first learned to play chords it seemed almost impossible to switch from one to the other. In time, my muscles memorized the movement and after a while I was able to do it without a thought. It's very similar with our machine. After a certain amount of time it feels natural.

We received an email from a recent customer who had this to say: Hi Rob, I absolutely love this machine. It was easy to assemble and I picked up the technique after 4 or 5 tries. I had a little difficulty making the initial seam, but after I did it a few times, I got the hang of it. Not sure why it takes most people 100 tries to master. Maybe my experience is not typical because I tried this with sheets of paper and watched every video out there. It makes things much easier for me, saves me a fortune ($1 a unit), is convenient because I can do it from home. I love everything about it. Thanks for your help. Stephen Trost This particular email really struck me because in earlier communications Stephen expressed a lot of concern over his abilities to do this type of work. He referred to himself as "the worlds biggest klutz" and yet he seems to have learned as quickly as anyone we have worked with. I believe this success is a result of two things. First, he committed himself to this project by watching every video we've made before he tried wrapping. Which brings me to part two of the success formula, our training videos. Donna does such a good job with this that she has taken hours of frustration out of the picture with just a few simple tips. So, the moral of this story is, if you are buying one of our machines then you will do yourself a huge favor if you will watch our Operating Tips video while your machine is in transit. Our first experience with manual overwrapping came several years ago when we purchased our first machine in response to our customers wanting a more professional look than the shrink wrap product we were providing at the time. So, we got our first machine and over time learned how to best use it. Part of that learning included what temperatures work best. If you set it too low it doesn't seal well and too high you can burn the film. We set that temperature years ago and have never changed it since.

Because we never change the temperature, when it came time to design the Xopax machines, we decided to have two different approaches to temperature control. Our goal was to design a basic system with a fixed temperature setting that is simple and easy to use while our upgraded system would allow temperature control and also provide us with a more durable electronics package that we could guaranty for three years. To that end we have ended up with what we are calling the PX Series and the PXC series. So, the purpose of this post is to help you decide which one works best for you . The first question you should ask is what thickness film are you using? If it is something radically different than the 1 mil film that 98% or our customers use then you should strongly consider the PXC so you an adjust your sealing temperature to compensate for the different thickness. If you're going to use the standard film then your next question is how much use is the machine going to get used? If you are going to use it a lot, meaning daily use for extended hours and want it to last for years, then the PXC is your best purchase. We back this unit for three years too. If your volume is low, the PX is a strong choice for economic reasons alone. The difference is in how we control the heat. With the PX we use some mechanical components that have a limited lifetime. These components on the PX are simple to replace by most end users and are going to be readily available from us. For this reason you don't need to worry about longevity but eventually the cost advantage may of the PX will deteriorate. We're talking hundreds of thousands of wraps before this would happen but we know some clients will wrap millions of boxes with our machines over years and years of use. One more item to add here is that if you choose the PX and one day have regrets we will be able to upgrade it for a reasonable price. |

AuthorRob Walker Archives

July 2016

Categories |

RSS Feed

RSS Feed